A Complete Guide to PET Preform Molds

2025-04-03

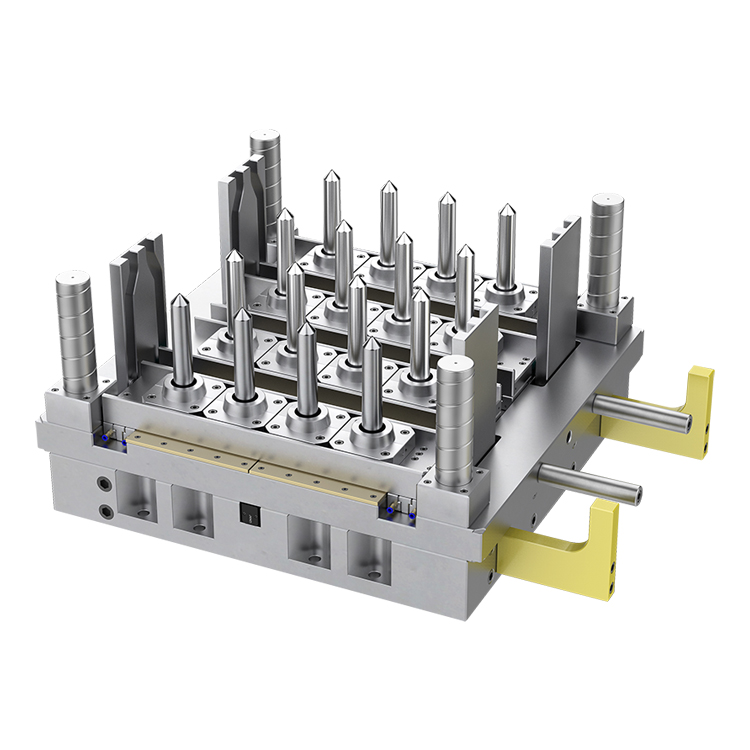

PET preform molds play a crucial role in the manufacturing of plastic bottles and containers. These molds are used in the injection molding process to create preforms, which are then blown into their final shape. Whether you are in the packaging industry or looking to understand how PET bottle production works, this blog will provide valuable insights into PET preform molds, their benefits, and their applications.

What Is a PET Preform Mold?

A PET preform mold is a specialized tool used in the injection molding process to shape polyethylene terephthalate (PET) material into preforms. These preforms have a test tube-like shape and serve as the base for producing plastic bottles and containers. Once created, the preforms undergo a blow molding process where they are heated and expanded into their final form.

How PET Preform Molds Work

The PET preform molding process consists of several key steps:

1. Injection Molding

Molten PET material is injected into the mold cavity at high pressure. The mold is designed to shape the preform according to precise specifications.

2. Cooling and Solidification

The preform is rapidly cooled within the mold to ensure uniformity and strength. Cooling channels help regulate temperature to prevent defects.

3. Ejection from the Mold

Once solidified, the preform is ejected from the mold. It is then ready for the next stage of production, which is blow molding.

4. Blow Molding and Final Shaping

The preform is heated and placed in a blow molding machine, where it is expanded into a bottle or container shape.

Benefits of Using PET Preform Molds

1. High Production Efficiency

PET preform molds are designed for mass production, allowing manufacturers to create thousands of preforms with precision and consistency.

2. Durability and Longevity

Made from high-quality materials such as stainless steel, these molds can withstand repeated use, ensuring long-term reliability.

3. Precision and Consistency

Advanced mold designs ensure uniform thickness and accurate dimensions, which is essential for maintaining product quality.

4. Cost-Effective Manufacturing

Using PET preform molds reduces material waste and production costs, making them an efficient solution for bottle manufacturing.

5. Versatility

These molds can be customized to create preforms of different sizes, weights, and neck finishes, catering to various industries such as beverages, pharmaceuticals, and cosmetics.

Applications of PET Preform Molds

PET preform molds are widely used in industries that require high-quality plastic packaging. Some common applications include:

- Beverage Bottles: Used for water, soft drinks, juices, and other liquid products.

- Pharmaceutical Containers: Designed for medical and healthcare packaging.

- Cosmetic Bottles: Used for shampoos, lotions, and beauty products.

- Household and Industrial Packaging: Suitable for cleaning agents, oils, and other chemical products.

Choosing the Right PET Preform Mold

When selecting a PET preform mold, consider the following factors:

- Cavity Number: Multi-cavity molds increase production capacity, while single-cavity molds are suitable for small-scale production.

- Material Quality: High-grade steel ensures durability and precision.

- Cooling System: Efficient cooling channels help improve production speed and quality.

- Customization Options: Choose a mold that fits your specific preform design requirements.

Maintenance Tips for PET Preform Molds

Proper maintenance of PET preform molds is essential to ensure long-lasting performance. Follow these best practices:

- Regular Cleaning: Remove dust, debris, and residues to prevent defects in preforms.

- Lubrication: Apply lubricants to moving parts to reduce friction and wear.

- Inspection and Repairs: Check for signs of wear and address any issues to avoid production delays.

- Temperature Control: Maintain optimal cooling and heating conditions to prevent damage to the mold.

Conclusion

PET preform molds are essential for the efficient production of plastic bottles and containers. They offer precision, durability, and cost-effectiveness, making them a valuable investment for manufacturers. By choosing the right mold and following proper maintenance practices, businesses can maximize productivity and ensure high-quality preforms for their packaging needs. Whether you are in the beverage, pharmaceutical, or cosmetics industry, PET preform molds play a key role in delivering reliable and sustainable packaging solutions.