Alumina Ceramic: The Material of Choice for Modern Technology

2025-04-10

Alumina ceramic, also known as aluminum oxide , is a highly versatile and durable material that plays a crucial role in modern technology. With its unique properties and wide range of applications, alumina ceramic has become an essential component in industries ranging from electronics to healthcare. Whether you are designing advanced electronic devices or creating high-performance machinery, alumina ceramic offers numerous benefits that make it the material of choice.

What is Alumina Ceramic?

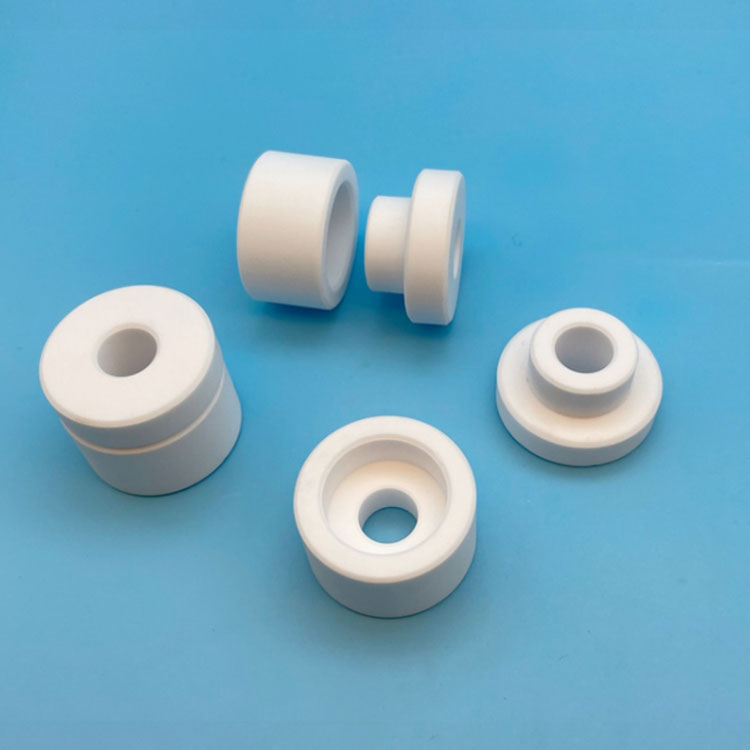

Alumina ceramic is a type of ceramic made from aluminum oxide, one of the most widely used ceramic materials. It is formed by sintering aluminum oxide powder at high temperatures, resulting in a hard, dense, and non-porous material. Alumina ceramics can vary in composition, purity, and form, depending on the specific requirements of the application.

One of the key reasons alumina ceramic is so popular is its exceptional hardness. On the Mohs scale, alumina ranks around 9, making it almost as hard as sapphire. This hardness, combined with its excellent thermal and electrical insulating properties, makes it ideal for a wide range of technical applications.

Key Properties of Alumina Ceramic

1. High Hardness and Wear Resistance: Alumina ceramic is extremely hard, which makes it resistant to abrasion, scratching, and wear. This property is particularly useful in applications that involve harsh conditions or mechanical stress.

2. Electrical Insulation: Alumina ceramics are excellent electrical insulators, making them ideal for use in electronics. They prevent the flow of electrical current, ensuring the safe operation of devices and components.

3. Thermal Stability: With its high melting point and low thermal expansion, alumina ceramic is highly stable at elevated temperatures. It can withstand extreme conditions without deforming, cracking, or losing its properties.

4. Corrosion Resistance: Alumina ceramic is resistant to chemical corrosion, making it suitable for use in environments where materials are exposed to acids, alkalis, and other aggressive substances.

5. Biocompatibility: Alumina is biocompatible, meaning it does not cause adverse reactions when in contact with biological systems. This makes it ideal for medical implants and devices.

Applications of Alumina Ceramic

The unique properties of alumina ceramic make it suitable for a wide variety of applications:

- Electronics: Alumina ceramics are used as substrates and insulators in electronic components like capacitors, resistors, and integrated circuits. Its electrical insulation properties ensure the safe operation of these components in electronic devices.

- Aerospace and Automotive: In the aerospace and automotive industries, alumina ceramic is used for parts that need to withstand high temperatures and mechanical stress, such as heat shields, engine components, and brake systems.

- Medical Devices: Alumina ceramics are used in medical applications like prosthetics and dental implants due to their biocompatibility, strength, and resistance to wear and corrosion.

- Industrial Machinery: Because of its high wear resistance, alumina ceramic is often used for components such as pumps, valves, bearings, and seals, which are exposed to abrasive materials.

- Cutting Tools: Alumina is used in the production of cutting tools, including drills, grinding wheels, and blades. Its hardness and resistance to abrasion make it ideal for machining tough materials.

Benefits of Using Alumina Ceramic

Alumina ceramic offers several advantages in various industries. Its exceptional durability ensures long-lasting performance in demanding environments, reducing the need for frequent replacements and maintenance. Its versatility allows it to be used in a wide range of applications, from electronics to manufacturing to healthcare.

Additionally, alumina ceramic’s insulating properties and high-temperature resistance make it a critical material for high-performance devices and systems that need to operate safely and reliably under extreme conditions.

Conclusion

Alumina ceramic has become an indispensable material in modern technology due to its remarkable properties, including high hardness, electrical insulation, thermal stability, and wear resistance. Whether it’s in electronics, aerospace, medical devices, or industrial applications, alumina ceramic provides the durability and performance needed to meet the demands of today's high-tech world. As technology continues to advance, the role of alumina ceramic will only grow, offering innovative solutions across various industries.