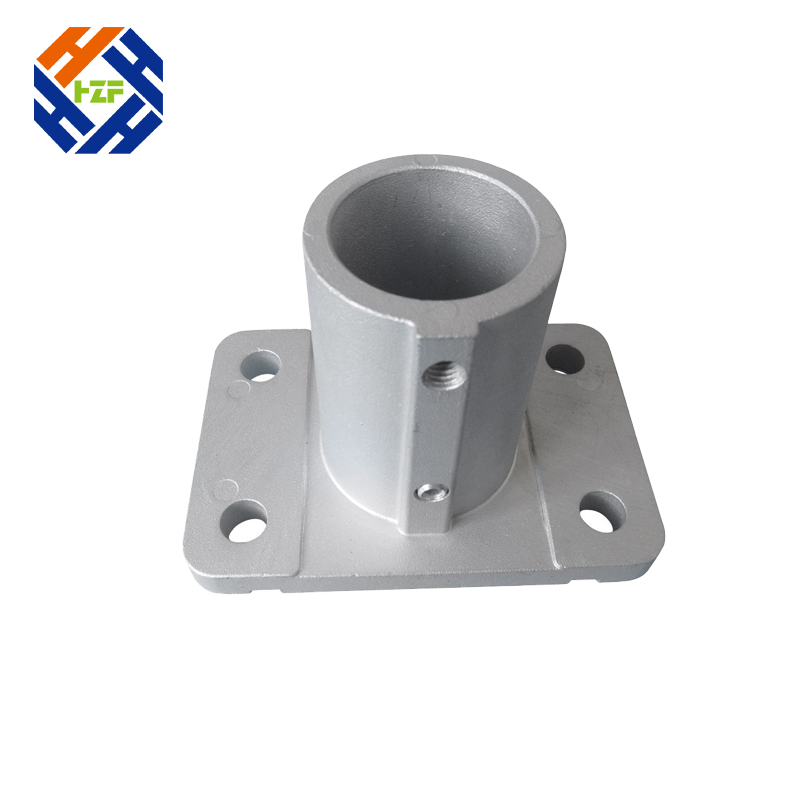

Aluminum Casting Parts: Durable and Versatile Components for Various Industries

2025-03-27

Aluminum casting parts play a crucial role in modern manufacturing, offering durability, lightweight properties, and excellent corrosion resistance. These components are widely used in industries such as automotive, aerospace, electronics, and construction. With advanced casting techniques, manufacturers can produce complex shapes and high-precision parts that meet the demands of different applications.

What Are Aluminum Casting Parts

Aluminum casting parts are components created by pouring molten aluminum into a mold, allowing it to solidify into a specific shape. This process ensures the production of strong, lightweight, and precisely engineered parts. Depending on the requirements, different casting methods are used, each offering unique benefits.

Common Aluminum Casting Methods

Die Casting

Die casting involves injecting molten aluminum into a steel mold under high pressure. This method produces parts with a smooth surface finish and high dimensional accuracy, making it ideal for mass production in industries such as automotive and electronics.

Sand Casting

Sand casting uses a sand mold to shape aluminum parts. It is suitable for producing large and complex components with detailed designs. This method is cost-effective for low-volume production and customized parts.

Gravity Casting

In gravity casting, molten aluminum is poured into a permanent mold using gravity rather than high pressure. This method creates strong and durable parts, often used in applications requiring high mechanical strength.

Investment Casting

Also known as lost-wax casting, this process involves creating a wax model, coating it with ceramic, and then melting the wax to leave a cavity for molten aluminum. It is ideal for intricate and detailed components with fine surface finishes.

Advantages of Aluminum Casting Parts

Lightweight and Strong

Aluminum casting parts provide an excellent strength-to-weight ratio, making them ideal for applications where weight reduction is essential, such as in aerospace and automotive industries.

Corrosion Resistance

Aluminum naturally forms a protective oxide layer, preventing rust and corrosion. This makes aluminum casting parts suitable for outdoor and marine environments.

High Thermal and Electrical Conductivity

These parts efficiently conduct heat and electricity, making them essential in electronic and heat dissipation applications, such as radiators and LED housings.

Cost-Effective Production

Aluminum casting allows for mass production with minimal material waste, reducing manufacturing costs while maintaining high quality.

Applications of Aluminum Casting Parts

Automotive Industry

Aluminum casting parts are used in engine components, transmission housings, wheels, and brake systems, improving vehicle efficiency and performance.

Aerospace Industry

Lightweight aluminum castings are essential for aircraft structures, turbine blades, and other aerospace components, ensuring durability without adding unnecessary weight.

Electronics and Electrical Equipment

Aluminum castings are used in heat sinks, enclosures, and connectors due to their excellent heat dissipation and electrical conductivity.

Construction and Machinery

From structural components to machine parts, aluminum castings provide strength and reliability in construction and industrial applications.

Choosing the Right Aluminum Casting Parts

When selecting aluminum casting parts for a specific application, consider factors such as

- Casting Method Choose the appropriate casting process based on precision, volume, and strength requirements.

- Material Grade Different aluminum alloys offer varying levels of strength, corrosion resistance, and conductivity.

- Surface Finish Ensure the part has the required finishing, such as anodizing or powder coating, for added durability and aesthetics.

Conclusion

Aluminum casting parts are essential in many industries due to their strength, lightweight nature, and corrosion resistance. With various casting methods available, manufacturers can produce high-quality components that meet specific requirements. Whether for automotive, aerospace, electronics, or construction, aluminum castings provide an efficient and cost-effective solution for modern engineering and manufacturing needs.