Considerations related to spliced wire rope slings

2023-11-16

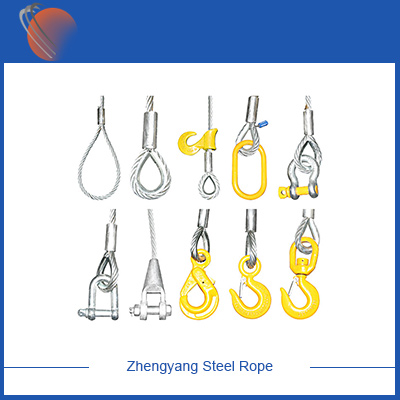

Spliced wire rope slings are a type of lifting sling made by forming an eye or loop at the ends of a steel wire rope through splicing. Splicing is a technique where the individual strands of the wire rope are interwoven to create a secure and strong termination. These slings are commonly used in lifting and rigging applications where flexibility and strength are crucial. Here are key features and considerations related to spliced wire rope slings:

1. Splicing Techniques:

- There are several techniques for splicing wire rope to create slings, including:

- Hand Tucked Eye: The individual wires are tucked back into the rope body, forming an eye.

- Flemish Eye: The rope is unlayed, and the strands are separated and tucked back to form an eye.

- Swaged Socket Eye: A socket is attached to the wire rope end using a swaging process, forming an eye.

2. Eye Types:

- Spliced wire rope slings can have different types of eyes, such as:

- Thimble Eye: A thimble is inserted into the eye to protect the rope from wear and deformation.

- Soft Eye: The eye is formed without a thimble, providing flexibility.

3. Single-Part and Multi-Part Slings:

- Spliced wire rope slings can be configured as single-part slings (with one continuous length of rope) or multi-part slings (with multiple legs).

4. End Terminations:

- The spliced ends of the wire rope can be terminated with hooks, links, or other fittings based on the application requirements.

5. Load Capacity and WLL:

- The Working Load Limit (WLL) of a spliced wire rope sling depends on factors such as the diameter of the rope, construction, and the type of splice. The WLL indicates the maximum load the sling is designed to lift safely.

6. Flexibility:

- Spliced wire rope slings offer flexibility, allowing them to adapt to the shape of the load. This flexibility is particularly useful in various lifting and rigging applications.

7. Durability:

- The durability of spliced wire rope slings is influenced by factors such as the quality of the splicing, the construction of the rope, and any additional protective measures (e.g., coatings or thimbles).

8. Inspection and Maintenance:

- Regular inspection is essential to identify signs of wear, broken wires, or other damage. Damaged slings should be taken out of service, and proper maintenance practices should be followed.

9. Environmental Considerations:

- Spliced wire rope slings can be galvanized or coated for additional protection against corrosion, making them suitable for outdoor or corrosive environments.

10. Usage Guidelines:

- Spliced wire rope slings should be used in accordance with the manufacturer's guidelines, industry standards, and applicable regulations for safe lifting practices.

11. Regulatory Compliance:

- Spliced wire rope slings must comply with relevant safety standards and regulations set by organizations such as OSHA (Occupational Safety and Health Administration).

Spliced wire rope slings are widely used in lifting and rigging operations due to their strength, flexibility, and versatility. Proper training in sling usage, regular inspections, and adherence to safety guidelines are essential for ensuring the safe and efficient use of spliced wire rope slings in various industrial settings.