Key Characteristics of Hot Rolled Steel Sheets

2024-06-12

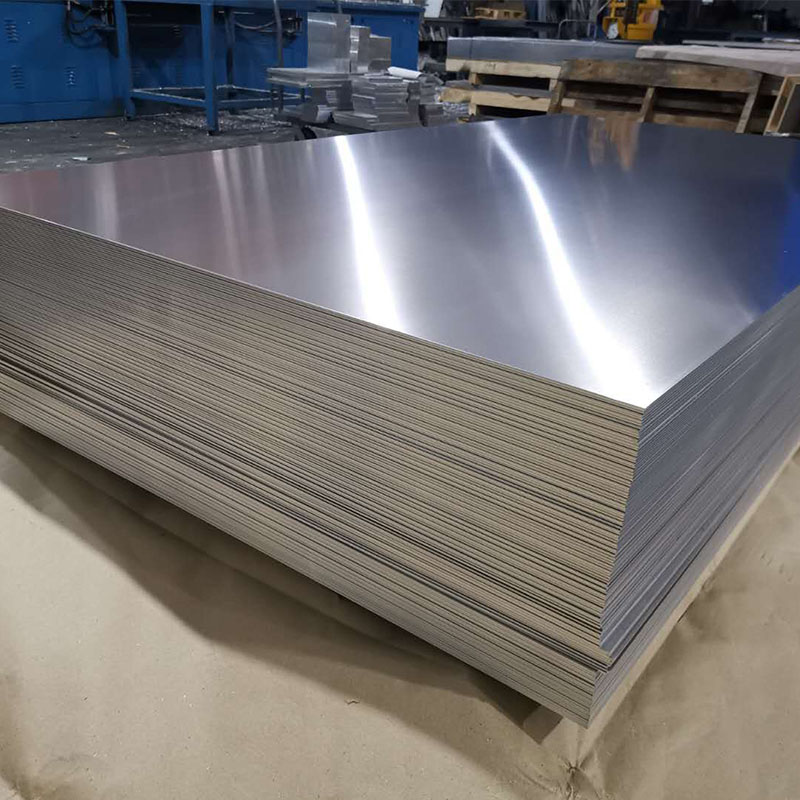

Hot rolled steel sheets are widely used in various industrial applications due to their versatility, strength, and relatively low cost. Here's a comprehensive overview of hot rolled steel sheets:

What is Hot Rolled Steel?

Hot rolling is a mill process that involves rolling the steel at a high temperature (typically over 1700°F or 926°C), which is above the steel’s recrystallization temperature. This makes the steel easier to shape and form, and the resulting product is free from internal stresses that can arise during the cooling process.

Key Characteristics of Hot Rolled Steel Sheets

1. Surface Finish:

- Typically has a rough, scaly surface that can be removed by grinding, sandblasting, or acid-bath pickling.

- Not as smooth as cold-rolled steel.

2. Dimensional Accuracy:

- Less precise compared to cold-rolled steel due to shrinkage and other variables during the cooling process.

- Thicker tolerances are common.

3. Mechanical Properties:

- Generally has lower tensile strength and hardness compared to cold-rolled steel.

- More ductile, making it easier to work with and form.

4. Sizes and Thicknesses:

- Available in a wide range of thicknesses, typically from 1.2mm to 25mm or more.

- Can be produced in larger sizes and heavier gauges compared to cold-rolled steel.

Production Process

1. Heating:

- Steel slabs or billets are heated to above their recrystallization temperature.

2. Rolling:

- The heated steel is passed through large rollers to achieve the desired thickness.

3. Cooling:

- The steel is then cooled at room temperature, which may cause slight warping or bending.

4. Cutting:

- The rolled steel is cut into sheets of desired sizes.

Applications

1. Construction:

- Structural components like I-beams, H-beams, and columns.

- Plates for construction of bridges, buildings, and other infrastructure.

2. Automotive:

- Frames, brackets, and other parts that require strength and durability.

3. Manufacturing:

- Machinery parts, heavy equipment, and agricultural machinery.

- Components that do not require a precise shape or smooth surface.

4. Shipping:

- Shipbuilding and marine applications for hulls and other parts.

5. Piping:

- Pipeline systems for oil and gas.

Advantages

- Cost-Effective: Lower production costs due to fewer processing steps.

- Versatile: Can be used in a variety of applications due to its strength and formability.

- Availability: Widely available in many sizes and thicknesses.

Disadvantages

- Surface Finish: Rough surface may require additional finishing steps.

- Dimensional Precision: Less precise dimensions compared to cold-rolled steel, requiring more careful handling in some applications.

- Mechanical Properties: Generally lower mechanical properties compared to cold-rolled steel.

Comparison with Cold Rolled Steel

- Cold Rolled Steel:

- Produced at room temperature after hot rolling.

- Smoother surface finish.

- Higher dimensional accuracy.

- Higher strength and hardness.

- More expensive due to additional processing.

- Hot Rolled Steel:

- Produced at high temperatures.

- Rougher surface finish.

- Less precise dimensions.

- More ductile and easier to work with.

- Lower cost.

Conclusion

Hot rolled steel sheets are a fundamental material in various industries due to their strength, workability, and cost-effectiveness. While they may require additional finishing steps for some applications, their versatility and wide availability make them a staple in construction, manufacturing, and other heavy-duty applications. Proper understanding of their properties and production process can help in selecting the right material for specific needs.