Key components of a drilling machine cell may include

2024-03-25

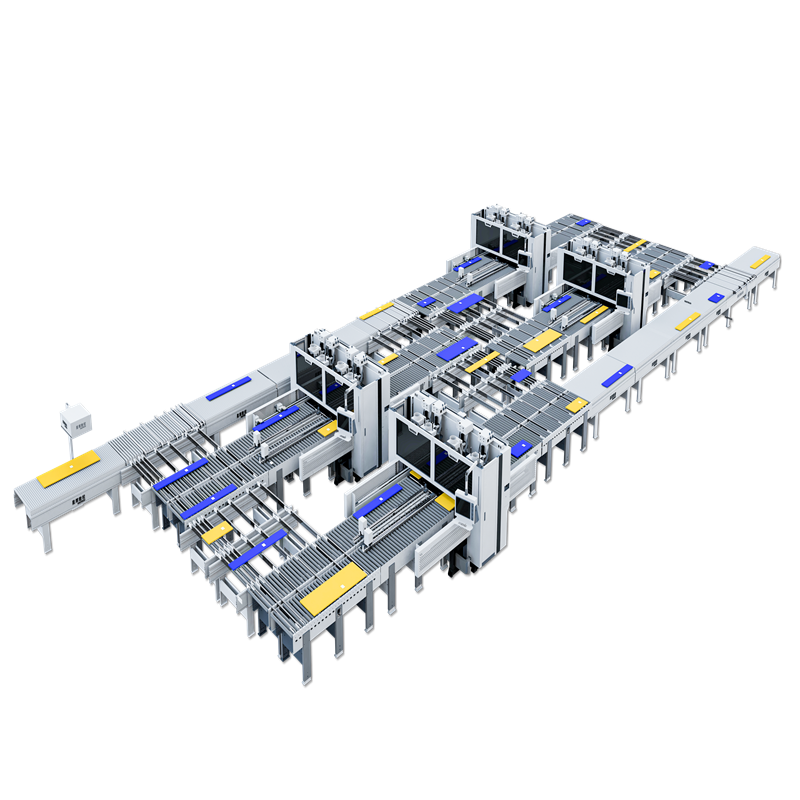

A drilling machine cell refers to a setup in manufacturing or industrial settings where multiple drilling machines are arranged in a systematic manner to perform various drilling operations efficiently. These cells are designed to optimize production processes, improve productivity, and ensure the smooth flow of workpieces through the drilling operations.

Key components of a drilling machine cell may include:

1. Drilling Machines: These are the primary equipment used for drilling operations. They can vary in types such as pillar drills, radial drills, CNC drilling machines, etc., depending on the requirements of the manufacturing process.

2. Workpiece Handling Systems: Automated systems or manual handling mechanisms are used to load and unload workpieces onto the drilling machines. This could involve conveyors, robotic arms, pallet changers, or human operators depending on the level of automation.

3. Tooling and Fixturing: Tooling and fixturing are essential to securely hold the workpieces in place during drilling operations and to ensure accuracy and repeatability. This may include clamps, jigs, fixtures, and specialized tooling for different types of drilling processes.

4. Safety Features: Safety measures such as emergency stop buttons, machine guards, and safety interlocks are crucial to protect operators and prevent accidents in the drilling cell environment.

5. Quality Control Systems: Inspection equipment and quality control measures may be integrated into the cell to ensure that drilled components meet the required specifications and quality standards.

6. Automation and Control Systems: Automation plays a significant role in drilling machine cells for improving efficiency and reducing human intervention. This involves programmable logic controllers (PLCs), CNC controls, sensors, and software for monitoring and controlling the drilling processes.

7. Material Handling and Chip Management: Systems for removing chips generated during drilling operations and managing coolant or lubricant fluids are necessary to maintain a clean and safe working environment.

Overall, the design and layout of a drilling machine cell are optimized to streamline the production process, minimize downtime, and maximize throughput while ensuring safety and quality standards are met. These cells are commonly found in industries such as automotive manufacturing, aerospace, metal fabrication, and others where drilling operations are integral to the production process.