Understanding the Importance of Heavy Duty Connector Inserts in Modern Industry

2025-04-09

In the world of electrical engineering and industrial applications, connectors are essential components for ensuring reliable and efficient communication between various parts of a system. Among the various types of connectors, heavy-duty connector inserts stand out due to their robustness, versatility, and ability to withstand demanding conditions. These inserts play a vital role in industries ranging from automotive to telecommunications and manufacturing.

In this blog, we will explore what heavy-duty connector inserts are, why they are crucial for industrial applications, and how they help ensure safe and reliable connections in various environments.

What is a Heavy Duty Connector Insert?

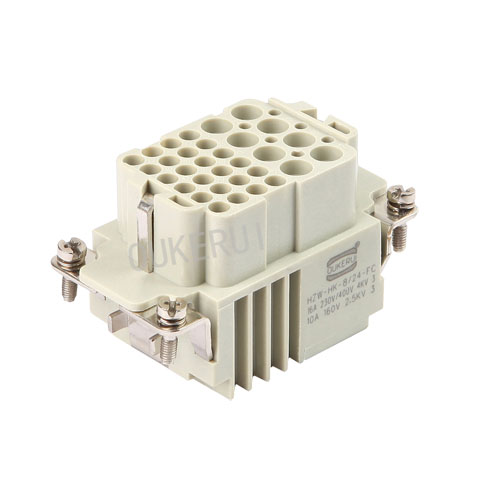

A heavy-duty connector insert is a key component of a connector system designed to provide reliable and secure electrical connections in harsh environments. The insert itself is typically made from materials that are resistant to extreme temperatures, moisture, vibrations, and other harsh conditions commonly found in industrial settings. These inserts are designed to fit inside a larger connector housing, and their primary function is to house the pins or contacts that establish the electrical connection between two parts of a system.

Heavy-duty connector inserts come in various sizes, configurations, and contact types, allowing for customization based on the specific needs of the application. They can support multiple connections, such as power, data, and signal transmission, ensuring that everything from machinery to communication devices operates seamlessly.

Why Are Heavy Duty Connector Inserts Important?

1. Durability in Harsh Conditions:

One of the most significant advantages of heavy-duty connector inserts is their ability to operate in challenging environments. Industries like aerospace, automotive, and manufacturing often require equipment that can withstand high levels of stress, including temperature extremes, vibration, moisture, and dust. Heavy-duty connector inserts are designed to meet these demands, ensuring that the electrical connections remain intact and reliable even in the harshest conditions.

2. Safety and Reliability:

The safety of personnel and the reliability of machinery are top priorities in any industrial setting. Using the right connector inserts helps ensure that electrical connections are secure and won’t lead to dangerous faults such as short circuits, electrical fires, or power failures. The strong, durable construction of these inserts minimizes the risk of failure, ensuring that systems continue to operate smoothly and safely.

3. Ease of Maintenance and Upgrades:

Heavy-duty connector inserts often feature modular designs, making them easy to maintain, repair, or upgrade. In industries that rely on machinery and equipment with complex wiring systems, being able to replace or upgrade a single connector insert can save time and money, preventing the need for complete system overhauls. This modularity also simplifies the troubleshooting process, as faulty connectors can be easily identified and replaced without disrupting the entire system.

4. Versatility Across Applications:

Another major benefit of heavy-duty connector inserts is their versatility. They are used across a wide range of industries, including telecommunications, automotive, railways, military, and industrial machinery. From connecting critical electrical systems in trains to ensuring communication equipment operates flawlessly in remote areas, heavy-duty connector inserts are integral to ensuring the smooth functioning of a variety of complex systems.

5. Enhanced Performance:

When it comes to high-performance machinery and equipment, every detail matters. Heavy-duty connector inserts help enhance the overall performance of the systems they are part of by providing stable and consistent electrical connections. This contributes to more efficient operation, better system responsiveness, and, ultimately, a more productive and reliable operation.

Applications of Heavy Duty Connector Inserts

Heavy-duty connector inserts are used in various fields, and their design is tailored to meet the specific requirements of different industries. Here are some of the common applications of heavy-duty connector inserts:

1. Automotive Industry:

In the automotive sector, heavy-duty connector inserts are used to ensure reliable electrical connections for everything from engine components to advanced driver-assistance systems (ADAS). These inserts are built to withstand high levels of vibration and temperature changes, ensuring the continued performance of critical systems within vehicles.

2. Telecommunications:

Telecommunication networks rely on heavy-duty connectors to ensure that data and signals can be transmitted reliably across long distances. Connector inserts in this sector must handle high-speed data, resist environmental elements, and support various connection types, from fiber optics to coaxial cables.

3. Industrial Equipment:

Manufacturing plants and industrial operations often use heavy-duty connector inserts to link electrical systems within complex machinery. These connectors help transfer power, data, and signals between machines on assembly lines, robotic systems, and other automated equipment, ensuring smooth operations with minimal downtime.

4. Aerospace:

The aerospace industry requires connectors that can perform reliably at extreme altitudes and in harsh weather conditions. Heavy-duty connector inserts in aerospace applications must meet strict safety and durability standards, as they are often used in critical systems such as avionics, navigation, and communication systems.

5. Rail and Transportation:

In rail transport, heavy-duty connector inserts are used to connect critical systems within trains, including power systems, lighting, and signaling. These connectors are designed to perform under vibration, humidity, and extreme temperatures, ensuring that transportation systems remain operational even in the toughest conditions.

6. Military and Defense:

Military-grade connector inserts are often required for equipment used in defense operations. These connectors must be able to resist shock, vibration, extreme temperatures, and exposure to chemicals. They are used in various applications, including communication systems, radar equipment, and military vehicles.

How to Choose the Right Heavy Duty Connector Insert

Selecting the right heavy-duty connector insert for your application requires careful consideration of several factors:

1. Environmental Conditions:

Determine the environmental factors the connector will be exposed to, such as temperature extremes, moisture, dust, and vibrations. Choose inserts that are rated for these specific conditions to ensure reliability.

2. Current and Voltage Requirements:

Different applications have different power needs. Choose a connector insert that can handle the required current and voltage to prevent overheating and electrical failures.

3. Size and Configuration:

Consider the physical space available for the connector. Heavy-duty connectors come in various sizes and configurations, so it's important to select one that fits your system.

4. Compatibility:

Ensure that the connector insert is compatible with your existing connectors and systems. Many manufacturers offer a range of inserts designed to fit specific connector housings.

Conclusion

Heavy-duty connector inserts are essential components in a wide range of industries, providing the durability, reliability, and performance needed to keep complex systems running smoothly. Whether in harsh environmental conditions or critical safety applications, these inserts ensure that electrical connections remain secure and dependable. By choosing the right heavy-duty connector insert, businesses can enhance the performance of their equipment, minimize downtime, and ensure safety and efficiency across their operations.