UV Printing on Aluminum Composite Panels: Revolutionizing Modern Signage and Design

2025-05-12

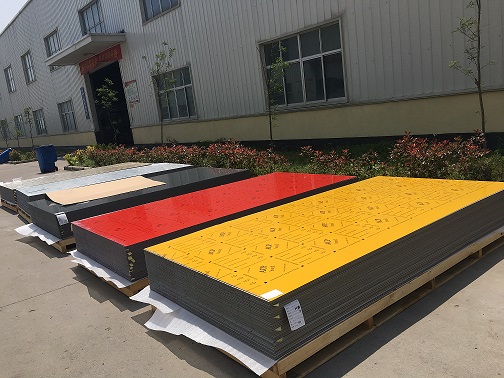

In the world of modern design and architecture, innovation is key to creating visually stunning and durable solutions. UV printing on aluminum composite panels (ACP) is one such breakthrough that has transformed the way we approach signage, building facades, and interior designs. With its vibrant color capabilities, long-lasting results, and environmental benefits, UV printing has quickly become the preferred method for printing on aluminum composite panels.

What is UV Printing?

UV printing is a digital printing technology that uses ultraviolet (UV) light to cure or dry the ink as it is printed. Unlike traditional printing methods, UV printing does not require a drying time because the ink is immediately cured by the UV light, allowing for faster production and enhanced durability.

The process involves printing directly onto a surface, such as an aluminum composite panel, with UV inks that are exposed to ultraviolet light to instantly harden. This results in prints that are more vibrant, resistant to wear, and suitable for both indoor and outdoor applications.

What is Aluminum Composite Panel (ACP)?

An aluminum composite panel (ACP) is a versatile material that consists of two thin layers of aluminum enclosing a non-aluminum core. This construction gives ACP a combination of strength, lightweight properties, and aesthetic appeal. ACPs are commonly used for exterior and interior cladding, signage, and displays.

They are known for their resistance to weathering, corrosion, and impact, which makes them ideal for both commercial and residential applications. With a smooth, durable surface, aluminum composite panels offer an excellent medium for UV printing, making them a popular choice for high-quality signage and architectural features.

The Benefits of UV Printing on Aluminum Composite Panels

1. Vibrant and Durable Prints

One of the main advantages of UV printing on aluminum composite panels is the ability to produce vibrant, high-resolution prints. The UV ink penetrates the surface of the panel, creating crisp details and rich, saturated colors that last. Additionally, the UV-cured ink is highly resistant to fading, making it ideal for both indoor and outdoor applications exposed to sunlight and harsh weather conditions.

2. Enhanced Durability

UV printing creates prints that are highly resistant to scratches, abrasions, and UV rays. This makes UV-printed ACPs ideal for applications such as exterior signage, building facades, and outdoor advertising, where materials need to withstand the elements for extended periods. The printed surface is also resistant to water, oil, and chemicals, further increasing its longevity.

3. Eco-Friendly Technology

UV printing is a more environmentally friendly option compared to traditional printing methods. The process uses UV light to cure the ink, which means there is no need for harmful solvents or excessive energy. Furthermore, the inks used in UV printing are low in volatile organic compounds (VOCs), making them safer for the environment and the people handling them.

4. Faster Turnaround Time

Traditional printing methods often require time for inks to dry, whereas UV printing cures the ink instantly. This results in a faster turnaround time, which is especially beneficial for businesses that need high-volume or quick-turnaround projects. The immediate curing also reduces the chances of smudging or contamination, ensuring the final product is of the highest quality.

5. Versatility in Design

UV printing allows for a wide range of design possibilities. Designers can print full-color images, logos, text, and intricate patterns directly onto the aluminum composite panel. This versatility makes UV printing suitable for various applications, including custom signs, corporate branding, architectural facades, and decorative panels. Additionally, UV printing can be used on panels with various finishes, such as matte, gloss, or textured, offering further customization options.

6. Strong Bond with the Surface

The UV ink bonds directly to the surface of the aluminum composite panel, providing a strong and lasting connection. This ensures that the print will not peel or fade easily over time. The durability of the bond makes UV printing ideal for high-traffic areas and environments where the print will be exposed to physical contact or the elements.

Applications of UV Printing on Aluminum Composite Panels

1. Signage and Branding

UV printing on ACPs is widely used for outdoor and indoor signage. Retailers, businesses, and government buildings often use UV-printed aluminum composite panels for directional signs, promotional displays, and large-format advertisements. The vibrant colors and weather-resistant properties of the print ensure that the signage remains clear and appealing even in harsh conditions.

2. Architectural Facades

Aluminum composite panels are commonly used for building facades due to their strength and aesthetic appeal. UV printing adds an extra dimension to these panels, allowing architects and designers to create custom patterns, graphics, and textures that enhance the visual appeal of buildings. UV printing can be used on both exterior and interior cladding, offering flexibility in design and functionality.

3. Interior Design

UV printing on ACPs is also used in interior design for custom wall panels, partitions, and decorative elements. Designers can create unique artwork, textures, and patterns that transform spaces into visually striking environments. The durability of UV printing ensures that these designs remain intact and vibrant, even in high-traffic or high-use areas.

4. Vehicle Graphics and Branding

Aluminum composite panels are often used in vehicle wraps and graphics, particularly for commercial fleets, buses, and trucks. UV printing allows for the reproduction of detailed and colorful images on these panels, ensuring that the graphics are eye-catching and long-lasting, even when exposed to the elements.

5. Retail Displays

UV-printed ACPs are commonly used in retail displays for promotional materials, point-of-sale signs, and product showcases. The durability of the print ensures that these displays maintain their professional appearance throughout the life of the display, making them a cost-effective solution for businesses that require high-quality, long-lasting signage.

Challenges and Considerations

While UV printing on aluminum composite panels offers numerous advantages, there are a few challenges to consider:

Surface Preparation: Proper surface preparation is crucial for achieving the best results. The aluminum composite panel must be clean and free of any oils, dust, or debris to ensure proper adhesion of the UV ink.

Cost: The initial investment in UV printing technology may be higher than traditional printing methods. However, the long-term durability and reduced maintenance costs often justify the expense.

Limited Flexibility on Certain Finishes: While UV printing works well on most aluminum composite panels, certain finishes (such as matte or heavily textured surfaces) may require additional adjustments in the printing process to achieve optimal results.

Conclusion

UV printing on aluminum composite panels has revolutionized the signage, architectural, and design industries by offering vibrant, durable, and environmentally friendly printing solutions. Whether you’re creating eye-catching signage, custom-designed building facades, or decorative interior panels, UV printing provides a high-quality, long-lasting, and versatile option for your printing needs. As technology continues to advance, UV printing is set to play an increasingly important role in shaping the future of design and advertising.