What Is a Cold Storage Insulation Panel and Why Is It Essential?

2025-07-10

In industries where temperature control is crucial—such as food storage, pharmaceuticals, logistics, and agriculture—Cold Storage Insulation Panels play a vital role in maintaining the required environment. These panels ensure that cold storage rooms, freezers, and refrigerated warehouses remain energy-efficient, durable, and reliable.

What Is a Cold Storage Insulation Panel?

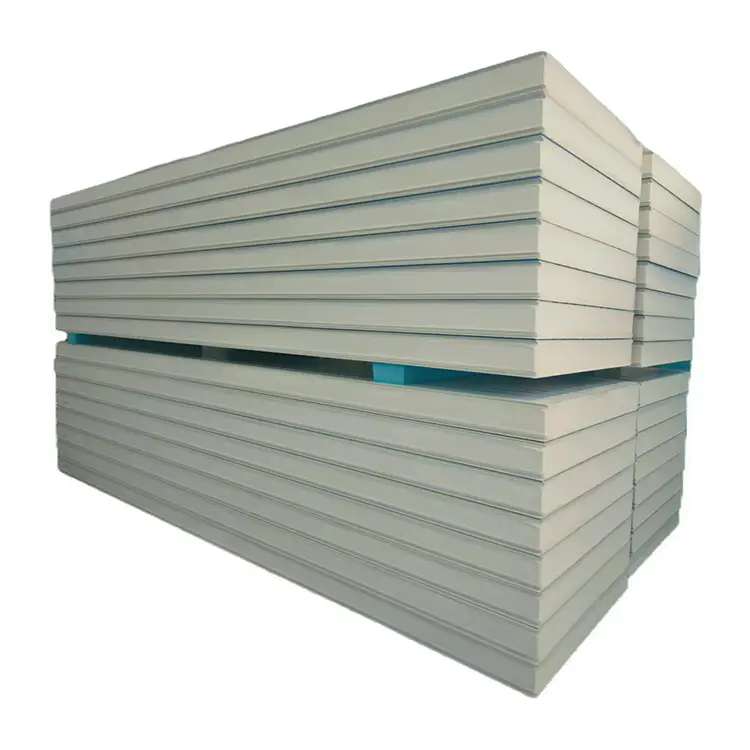

A Cold Storage Insulation Panel is a prefabricated building material designed to provide superior thermal insulation for cold rooms and refrigerated environments. These panels are typically constructed with insulating cores such as Polyurethane (PU), Polyisocyanurate (PIR), or Expanded Polystyrene (EPS), sandwiched between two layers of protective facing, usually made of color-coated steel sheets or stainless steel.

The main purpose of these panels is to minimize heat transfer, helping maintain consistent low temperatures inside the storage area.

What Are the Advantages of Using Cold Storage Insulation Panels?

Excellent Thermal Insulation: Keeps internal temperatures stable, reducing energy consumption.

Quick Installation: Prefabricated panels are easy to assemble, saving time and labor costs.

Durability: High-quality steel facings ensure long-term structural integrity.

Hygienic and Easy to Clean: Essential for food and medical storage environments.

Customizable Sizes and Thickness: Suitable for various temperature requirements and space constraints.

Where Are Cold Storage Insulation Panels Commonly Used?

These panels are widely used in:

Cold Rooms & Freezers

Refrigerated Warehouses

Food Processing Plants

Pharmaceutical Storage

Supermarkets & Distribution Centers

Flower Storage Facilities

How to Choose the Right Cold Storage Insulation Panel?

When selecting insulation panels for cold storage, consider:

Temperature Requirements: Lower temperatures demand thicker panels.

Core Material: PU and PIR offer better insulation values, while EPS is a more economical option.

Fire Resistance: PIR panels typically provide higher fire safety.

Panel Thickness: Ranges commonly from 50mm to 200mm depending on the cooling needs.

Moisture Resistance: Ensures longevity and hygiene inside the cold room.

Conclusion

A Cold Storage Insulation Panel is a key component in building energy-efficient and effective refrigerated spaces. With excellent insulation properties, durability, and ease of installation, these panels help businesses in the food, pharmaceutical, and logistics sectors maintain product quality while reducing operational costs. Investing in the right insulation panel is essential for any cold storage facility aiming for high performance and sustainability.