Why Are Conveyor Idlers Essential for Efficient Material Handling?

2024-12-13

In industries where materials are constantly being moved, whether it's mining, construction, or manufacturing, the efficiency of the conveyor system plays a critical role in maintaining productivity. One of the most important components of these systems is the conveyor idler. But what exactly is a conveyor idler, and why is it so essential for the smooth operation of material handling processes?

Let’s explore the significance of conveyor idlers and how they contribute to the overall efficiency of conveyor systems.

What is a Conveyor Idler?

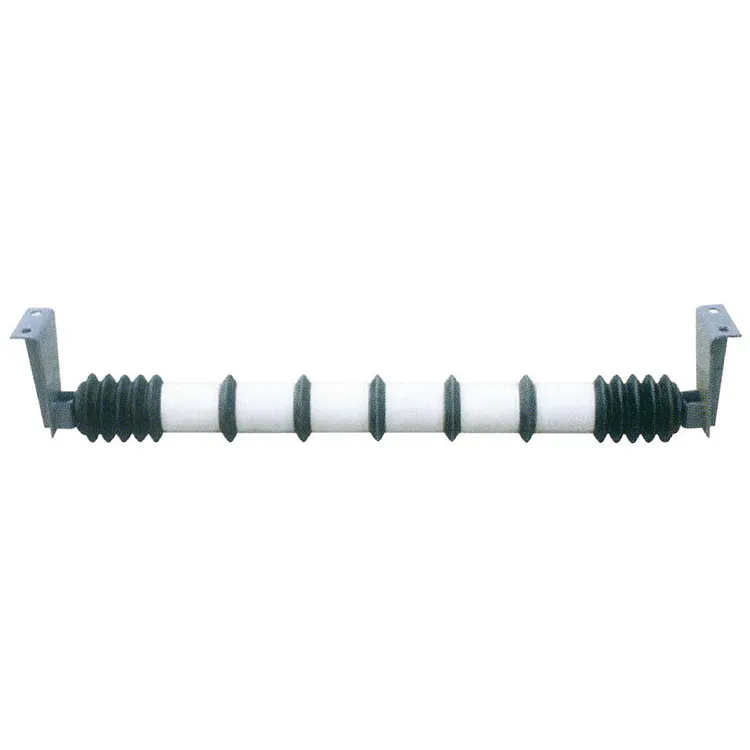

A conveyor idler is a cylindrical component used to support the belt of a conveyor system. Positioned along the conveyor’s length, idlers play a crucial role in maintaining the tension of the conveyor belt and helping it move materials from one point to another. Idlers are mounted on a rotating shaft and can be positioned at various points on the conveyor, depending on the specific design and requirements.

There are different types of idlers, including return idlers, impact idlers, and trough idlers, each designed for specific functions within the system. The primary function of a conveyor idler is to provide support to the conveyor belt, ensuring its smooth operation and helping to reduce wear and tear.

Why Are Conveyor Idlers So Important?

1. Smooth and Continuous Operation

The primary purpose of a conveyor idler is to ensure the smooth running of the conveyor belt. When the belt is supported properly, it can move smoothly, reducing friction and preventing unnecessary stress. This results in fewer interruptions and increased uptime, which is crucial for maintaining continuous production in industries like mining, manufacturing, and logistics.

By offering consistent support, idlers help maintain proper tension in the conveyor belt, which in turn ensures the optimal performance of the system.

2. Reduction in Wear and Tear

Conveyor belts are subjected to constant friction as they move materials across various points. Over time, this friction can lead to significant wear and tear, causing the belt to break down faster. Idlers play a crucial role in reducing this friction by providing support at various points along the belt, helping to distribute the load evenly.

Additionally, idlers are designed to handle the weight of the material being moved, preventing excessive pressure on the belt. By supporting the belt effectively, idlers extend its lifespan and reduce the need for costly repairs or replacements.

3. Improved Load Distribution

Conveyor systems are often used to transport large and heavy loads, and ensuring that these loads are evenly distributed across the belt is vital for efficient operation. Conveyor idlers help to distribute the load evenly, preventing the belt from sagging or becoming misaligned. This ensures that materials are moved efficiently and that the belt maintains its structural integrity, reducing the chances of damage to the system.

4. Increased Conveyor System Efficiency

A well-functioning conveyor system relies on each component working together to achieve maximum efficiency. Conveyor idlers contribute to the overall efficiency by ensuring that the belt operates smoothly and without unnecessary friction. When idlers are properly maintained and aligned, the system can run at optimal speeds, reducing energy consumption and improving throughput.

5. Reduced Maintenance Costs

When idlers are properly installed and maintained, they help to keep the entire conveyor system running efficiently. As a result, there are fewer breakdowns, less frequent need for repairs, and reduced wear on other components of the system. This leads to lower maintenance costs and improved reliability, saving businesses money in the long run.

Proper maintenance of idlers is key to extending the life of the conveyor system and minimizing unplanned downtime. Regular inspections and timely replacements can help prevent costly repairs and replacements of other more expensive parts of the system.

6. Protection Against Environmental Conditions

In some industries, conveyor systems operate in harsh environments, exposed to dust, moisture, and extreme temperatures. Conveyor idlers are designed to withstand these challenging conditions, ensuring that the system remains functional despite external factors.

For example, impact idlers are often used in areas where heavy materials are dropped onto the conveyor belt, helping to absorb the shock and prevent damage to the belt. Similarly, weather-resistant materials can be used for idlers operating in outdoor environments, ensuring the durability and performance of the system.

7. Versatility and Customization

Conveyor idlers come in various designs and configurations, depending on the specific needs of the conveyor system. Some idlers are designed for high-capacity, heavy-duty applications, while others are built for lighter loads. There are also idlers designed for different belt types, load conditions, and angles of incline.

This versatility allows for the customization of conveyor systems to meet the demands of various industries. Whether for transporting bulk materials or delicate products, idlers can be adapted to ensure the efficient and safe movement of goods.

Applications of Conveyor Idlers

Conveyor idlers are used in a variety of industries, thanks to their ability to support and improve the efficiency of conveyor systems. Some common applications include:

- Mining: Used to transport coal, ores, and other materials in mining operations.

- Agriculture: For moving grains, seeds, and other agricultural products.

- Construction: Transporting sand, gravel, and other construction materials.

- Logistics: Handling packages and parcels in warehouses and distribution centers.

- Manufacturing: Moving raw materials or finished products through production lines.

Conclusion

Conveyor idlers are an essential component in the efficient functioning of conveyor systems across many industries. They ensure smooth and continuous operation, reduce wear and tear, distribute loads evenly, and increase system efficiency. Moreover, their ability to reduce maintenance costs and extend the lifespan of the conveyor belt makes them a valuable investment for businesses seeking to improve their material handling processes.

In the world of material handling, where speed, reliability, and cost-efficiency are paramount, conveyor idlers are a small but crucial part of the puzzle. Whether it’s mining, manufacturing, or logistics, investing in high-quality idlers can make all the difference in achieving optimal performance.