Why is FRP Grating the Best Choice for Industrial Flooring and Applications?

2024-12-24

In industries that require durable, high-performance flooring solutions, FRP grating (Fiberglass Reinforced Plastic grating) has become an essential choice. But why is FRP grating the best choice for various industrial flooring and applications? From its impressive strength-to-weight ratio to its resistance to harsh chemicals and environmental factors, FRP grating offers several advantages that make it the go-to material in demanding environments. In this blog, we will dive into the key reasons why FRP grating is gaining popularity across industries such as manufacturing, construction, and utilities.

What is FRP Grating?

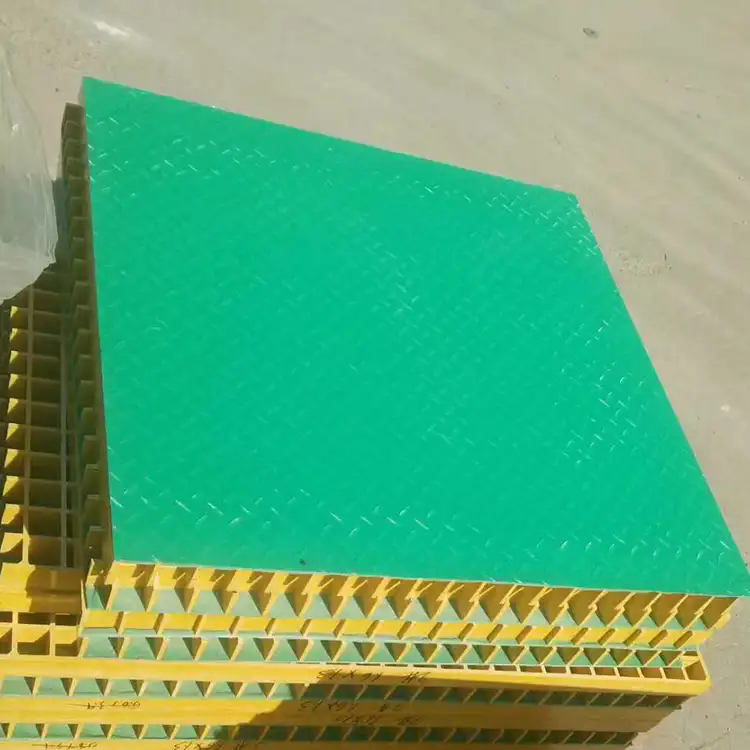

FRP grating is a type of grating made from a composite material of fiberglass and resin. This combination results in a material that is both lightweight and incredibly strong, making it ideal for flooring, walkways, and platforms in industrial settings. Unlike traditional steel grating, FRP grating does not corrode and can withstand the challenges posed by chemicals, moisture, and extreme temperatures. It is designed with a series of open spaces between the bars, which allows for water drainage and easy cleaning—features that make it perfect for industrial environments.

Why Choose FRP Grating?

1. Exceptional Durability and Longevity

One of the standout features of FRP grating is its remarkable durability. FRP grating is highly resistant to corrosion, rust, and chemical degradation. This makes it the ideal choice for industries where corrosive substances or wet conditions are common, such as chemical plants, wastewater treatment facilities, and food processing plants. Unlike metal grating, FRP grating doesn’t need frequent maintenance or replacement, ensuring long-term use and cost savings.

2. Lightweight and Easy to Handle

FRP grating is significantly lighter than traditional materials like steel or aluminum, which makes it easier to transport, install, and handle. Despite its lightweight nature, it maintains strength and can support heavy loads, which is crucial for industrial applications. The reduced weight not only cuts down on labor costs during installation but also makes it easier to modify or reposition if needed.

3. High Strength-to-Weight Ratio

The combination of fiberglass and resin creates a material that has an excellent strength-to-weight ratio. FRP grating can handle high loads and heavy traffic without compromising its structural integrity. Whether used for walkways, platforms, or flooring, FRP grating provides a stable and reliable surface for workers and machinery.

4. Resistance to Chemicals and Environmental Factors

In industrial environments, exposure to chemicals, moisture, and extreme temperatures is often inevitable. FRP grating excels in these environments because it is highly resistant to corrosion and chemical attack. It can withstand exposure to a variety of chemicals, including acids, alkalis, and solvents, which would otherwise degrade other materials. Additionally, FRP grating is UV-resistant, making it ideal for outdoor use where sunlight and temperature fluctuations can cause materials to break down over time.

5. Non-Conductive and Safe for Use

Another key benefit of FRP grating is its non-conductivity. It does not conduct electricity, making it a safer alternative to metal grating in environments where electrical hazards are present. This makes FRP grating particularly useful in industries such as power generation, electrical utilities, and oil and gas, where electrical safety is critical.

6. Ease of Installation and Maintenance

FRP grating is easy to install, and its lightweight nature reduces labor costs. It is available in various sizes and thicknesses, allowing for easy customization to fit the specific needs of any project. Once installed, FRP grating requires minimal maintenance. Its smooth surface is resistant to dirt buildup, and any accumulated debris can be washed off easily, making it an excellent option for hygienic environments, such as food production or pharmaceutical industries.

7. Customizable Options

FRP grating comes in a wide range of designs, including molded, pultruded, and extruded types, to accommodate different project requirements. Additionally, it can be customized with anti-slip surfaces, making it safer in environments where slip hazards are a concern. The versatility in design options makes FRP grating suitable for a wide variety of applications, from industrial walkways to stair treads and drainage covers.

Where is FRP Grating Used?

1. Industrial Flooring

FRP grating is often used for flooring in industries where corrosive substances are present or where the environment is wet or humid. It is commonly seen in chemical plants, refineries, and pharmaceutical facilities, where durability and chemical resistance are essential.

2. Walkways and Platforms

In manufacturing and construction, FRP grating is used to create safe and durable walkways, platforms, and catwalks. Its lightweight nature makes it easy to install, and its non-slip surface ensures safety even in slippery environments.

3. Wastewater Treatment Facilities

The corrosion resistance of FRP grating makes it an ideal choice for wastewater treatment plants. The constant exposure to water and chemicals can degrade other materials, but FRP grating remains stable and reliable in these harsh environments.

4. Marine Applications

FRP grating is frequently used in marine environments where exposure to saltwater, moisture, and UV radiation is inevitable. It is used for docks, piers, and ship decks, providing a non-slip and corrosion-resistant surface that is safe for workers.

5. Oil and Gas Industry

The oil and gas industry often uses FRP grating for platforms and walkways due to its resistance to harsh chemicals, oils, and extreme weather conditions. Its non-conductivity also makes it safe in environments with electrical risks.

6. Food Processing and Beverage Industry

In food processing facilities, cleanliness is critical. FRP grating’s resistance to corrosion and ease of cleaning make it an excellent choice for creating hygienic, safe flooring systems in these environments.

Is FRP Grating Cost-Effective?

While the initial cost of FRP grating may be higher than traditional materials like metal or wood, its long lifespan and minimal maintenance needs make it a cost-effective solution in the long run. The resistance to corrosion and wear means that FRP grating will not need frequent replacement or repairs, saving businesses money over time. Additionally, the ease of installation reduces labor costs, further enhancing its cost-effectiveness.